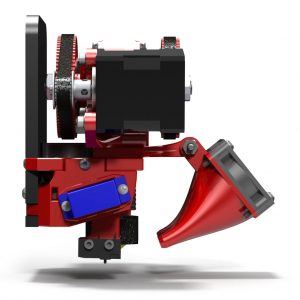

The Itty Bitty Double FLEX V2 is the third generation of the Clough42 Itty Bitty Double Extruder. This new version incorporates:

The Itty Bitty Double FLEX V2 is the third generation of the Clough42 Itty Bitty Double Extruder. This new version incorporates:

- Tighter filament channel for better flexible filament performance

- Support for Hexagon AO hot ends

- Redesigned parts for easier printing and less cleanup

- Low-profile shelf brackets for side-registering endstop switches

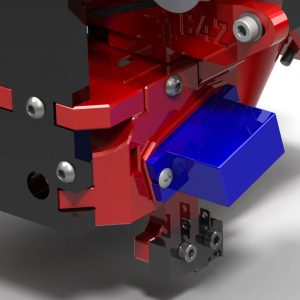

- Support for more Z probe switches

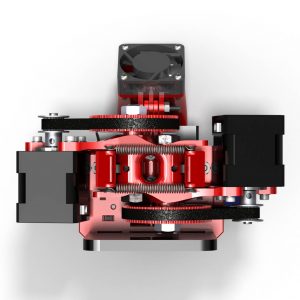

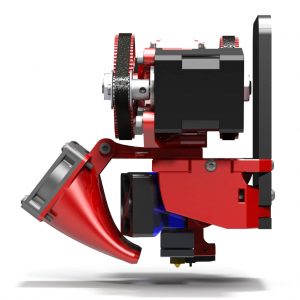

Key Features:

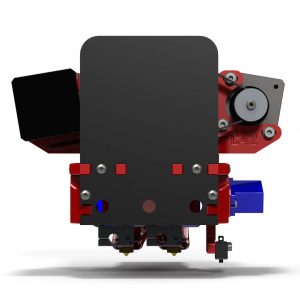

- Designed for Hexagon or E3Dv6 hot ends on 27mm centers

- Short, straight filament path to accommodate flexible materials

- Uses the same hardware kit as all Itty Bitty Double Extruders

- NEMA 14 motors

- Silent GT2 belt drives with printed pulleys

- Integrated servo Z probe

- Cam-lock idler bearing pins

- Uses our custom hobbed bolts (or equivalent)

- Lighter than a stock single Accessible Extruder

- Integrated hot end cooling

- Mounting hardware for Prusa i3v printers

Gallery

Which Extruder Do I Need?

The Itty Bitty Double FLEX Extruder V2 is the latest evolution of the original Itty Bitty Double Extruder. All Itty Bitty double extruders use the same hardware and offer dual extrusion support on MakerFarm printers. Here are the differences:

Itty Bitty Double FLEX V2 Extruder:

- Better flexible filament control

- Supports Hexagon AO

- Designed for easier printability with less cleanup

- Low-profile shelf brackets to support underslung X endstops

- Support for more Z probe switch types

Itty Bitty Double FLEX Extruder:

- Short, straight filament path for easier printing of flexible filament

- Support for both Hexagon and E3Dv6 hot ends (NOTE: NOT Hexagon AO)

- Wider (27mm) nozzle spacing reduces usable bed area slightly

- Greater overall width (fits fine on i3v)

Itty Bitty Double Extruder (original):

- Long, curved filament path works best with rigid filaments

- Designed for Hexagon hot ends (NOTE: NOT Hexagon AO)

- Narrow (20mm) nozzle spacing for maximum usable bed area

- Narrower overall width may fit more printers

If you need to print flexible filaments or use E3Dv6 hot ends, you want the extruder on this page: the Itty Bitty Double FLEX. If you need more usable bed area or have a printer with limited space (like the original rod-style i3) you may wish to consider the original Itty Bitty Double Extruder. Version 1 of the Itty Bitty Double FLEX Extruder is still availble for reference.

Printable Files

Download the printable files here:

Itty Bitty Double FLEX V2 Extruder Printable Parts

All of the files are included for the entire extruder system for 1.75mm and 3mm filament, Hexagon and E3Dv6 hot ends. To assemble the entire system you will need to print:

One extruder block:

- For 3mm hot ends: Double Flex Block-300Universal.STL

- For 1.75mm hot ends without a liner: Double Flex Block-175Universal.STL

- For 1.75mm E3D hot ends with a PTFE liner and fitting: Double Flex Block-175E3dLiner.STL

Hot end-specific parts:

- Hexagon hot ends: All of the parts in the “Hexagon Specific” folder. An alternate fan shroud is provided for the Hexagon AO.

- E3D hot ends: All of the parts in the “e3dv6 Specific” folder

Common parts:

- All of the parts in the “Common Parts” folder

You will need two copies each of the idler blocks, idler pins, pulleys and round spacers and one copy of everything else.

Required Hardware

In addition to the printed parts, you will need the following vitamins:

- Hardware kit

- Available in our store: Itty Bitty Double Extruder Hardware Kit

- GT2 20-tooth Pulleys with set screws (2)

- GT2 200mm Belts (2)

- 688ZZ 8x16x5mm Bearings (6)

- Extension springs (2)

- Fiberglass/Polyimide insulator

- M2.5×10 socket head cap screws (2)

- M4x.7 hex nuts (2)

- M4x20 button head cap screws (2)

- M3 flat washers (6)

- M3x.5 hex nuts (11)

- M3x25 socket head cap screws (3)

- M3x16 button head socket cap screws (10)

- M3x12 flat head socket cap screws (10)

- M3x8 socket head cap screws (6)

- M3x6 button head socket cap screws (2)

- Light double extruder springs (optional – for flexible filament)

- Available in our store: Light Double Extruder Springs

- Hobbed bolts with jam nuts (2)

- Available in our store: Hobbed Extruder Bolt

- Hot Ends (matched pair)

- Hexagon

- E3Dv6

- NEMA 14 stepper motors (2)

- Available in our store: NEMA 14 Stepper Motor

- HXT-900 Servo

- Available in our store: HXT-900 Servo

- Z probe switch

- You can use virtually any snap switch, including the one that came with your MakerFarm printer.

- 25x25x10mm fan (Hexagon hot ends only)

- The 25mm fan included with most Hexagon hot end kits will work fine

- Recommended upgrade: http://www.digikey.com/product-search/en?KeyWords=259-1570-ND

- 40x40x10mm fan (for print cooling)

- A 40mm fan is now included with most Hexagon hot ends

Assembly and Calibration

Assembly and calibration instructions are available here:

Additional Resources

Discussion thread on 3DPrintBoard