Toolpost Grinder Part 5: Spacers

Today, we’re working on the toolpost grinder again. This time, we make the brass spacers. We need the spacers because the lock rings block direct access to the inner bearing races. Locking the bearings in place like this makes them … Continued

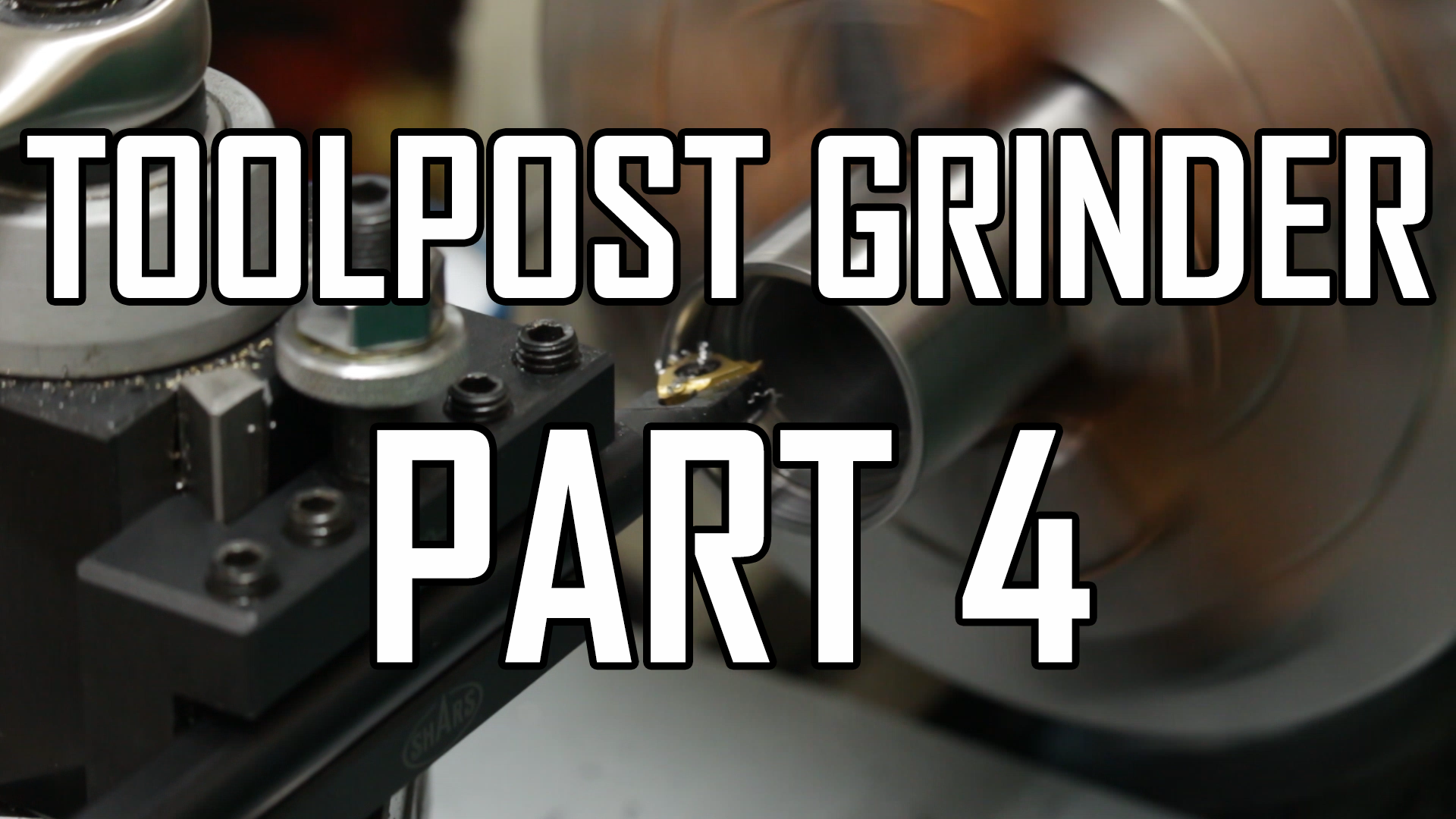

Toolpost Grinder Part 4: Fitting the Caps

The time has finally come to fit the bearings and bearing caps into the toolpost grinder spindle. In this installment, we cut the internal threads in the spindle body to accept the bearing caps, lock in the bearings and face … Continued

Toolpost Grinder Part 3: Bearing Caps

In part three of the toolpost grinder build series, we make the bearing lock caps. This installment features the return of the dreaded 57/64″ YG-1 taper-shank drill, but this time it does its job without complaining. Or damaging the lathe. … Continued

Toolpost Grinder Build Part 2: Spindle Body

In part two of the toolpost grinder series, we get started by turning the spindle body out of a chunk of 12L14 mild steel. This turns out to be a bigger job than imagined, and we find out some of … Continued

Toolpost Grinder Build Part 1: Introduction

I have always wanted a toolpost grinder for my lathe. As we’ve built out the shop here at Clough42, I’ve made more than a few arbors for drill chucks, face mills, boring heads, slitting saws and other cutting tools. They … Continued

New machine shop goodness!

Here at Clough42, we’re trying something new. Until now, we’ve been focused almost entirely on 3D printing. But behind the scenes, we’ve been building up a small machine shop for product development and prototyping. Today, we’re inviting you inside! We’re … Continued

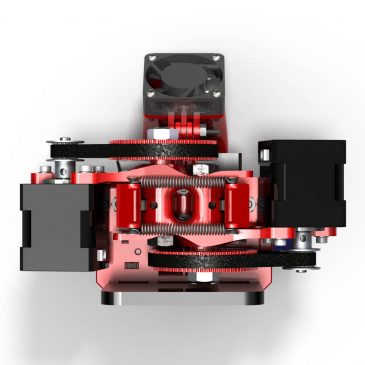

Itty Bitty Double FLEX V2.1 Minor Update

We have just released version 2.1 of the Itty Bitty Double Extruder. This is a minor update that fixes a few issues: Added longer versions of the Hexagon and E3Dv6 Z probe arms to work with shorter snap switches that … Continued

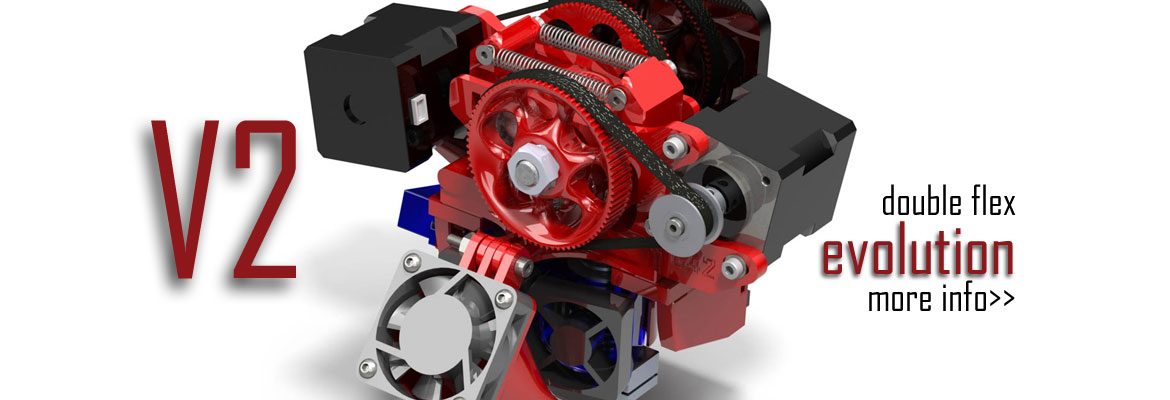

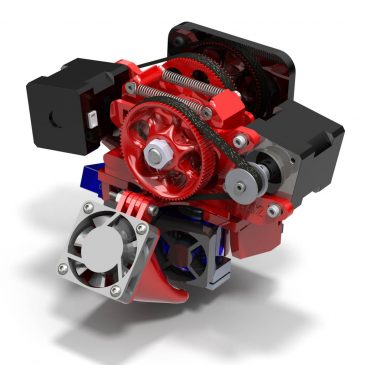

The V2 Evolution Is Here

Introducing the Itty Bitty Double FLEX V2 Extruder. This latest evolution in the Clough42 double extruder lineup adds: Tighter filament channel for better flexible filament performance Support for Hexagon AO hot ends Redesigned parts for easier printing and less cleanup … Continued

We Now Have Hobbed Extruder Bolts!

We now have hobbed extruder bolts in stock and ready to ship. We really think you’ll like this addition to our product lineup. We mill these bolts in house, specifically for our extruders. They provide a secure grip on the … Continued

Troubleshooting FAQ

Need a little help getting your extruder working? We get questions from users almost every day, and we’ve collected the most common ones into a Frequently Asked Questions (FAQ) list to help you out. Extruder Troubleshooting FAQ